China Custom Supply Manipulator Parts Company For Sale Price

Manipulator parts are critical components within automation systems, facilitating efficient handling and manipulation of materials across various industrial sectors. These components are designed to enhance precision, reliability, and versatility in automated processes, contributing significantly to operational efficiency and productivity.

At the core of every manipulator is the robotic arm, a mechanical structure comprised of interconnected segments and joints. These joints enable the arm to articulate and maneuver in multiple directions, similar to the range of motion of a human arm. Constructed from materials like aluminum alloys or carbon fiber, robotic arms are lightweight yet robust, capable of supporting various payloads while maintaining agility and durability in demanding environments.

End effectors, also known as grippers or tooling, are attachments mounted at the end of robotic arms to interact with workpieces. These components are designed with specific functionalities tailored to tasks such as gripping, lifting, rotating, or manipulating objects of different shapes and sizes. End effectors come in diverse configurations, including mechanical grippers, vacuum suction cups, magnetic grippers, and specialized tools equipped with sensors for precise control and manipulation.

Manipulator joints are pivotal points along the robotic arm where motion is articulated and controlled. Actuators, such as electric motors, pneumatic cylinders, or hydraulic systems, provide the necessary power to drive these joints, enabling precise movements and adjustments. Advanced manipulators often integrate servo motors or stepper motors combined with feedback systems to ensure accurate positioning and motion control, enhancing operational efficiency and reducing cycle times in automated processes.

Sensors play a crucial role in manipulators by providing real-time feedback on position, orientation, force, and environmental conditions. These sensors enable manipulators to perceive and respond dynamically to changes in their surroundings, ensuring safe and accurate operation. Commonly used sensors include encoders for position feedback, force/torque sensors for measuring interaction forces, proximity sensors for detecting objects, and vision systems for visual guidance and inspection tasks.

The control system serves as the brain of the manipulator, orchestrating the operation of all components to execute predefined tasks with precision and efficiency. It comprises hardware components such as microcontrollers, PLCs (Programmable Logic Controllers), and drive systems, coupled with software algorithms that process sensory inputs, execute motion profiles, and implement safety protocols. Advanced control strategies, including PID (Proportional-Integral-Derivative) control and adaptive algorithms, optimize manipulator performance while ensuring compliance with operational requirements and safety standards.

Manipulators require a reliable power supply and efficient cabling infrastructure to deliver electrical power and communication signals throughout the system. Power distribution units, cables, and wiring harnesses are designed to withstand mechanical stress, environmental conditions, and electromagnetic interference, ensuring seamless integration and operation of manipulator components in industrial environments.

Safety features are integral to manipulator design to protect operators, equipment, and surrounding environments from potential hazards. These features include emergency stop mechanisms, protective barriers, collision detection sensors, and software-based safety protocols that enforce safe operating limits and behaviors. Ergonomic considerations ensure user-friendly interfaces, intuitive programming tools, and ergonomic designs that enhance operator comfort and efficiency during manual interaction or maintenance tasks.

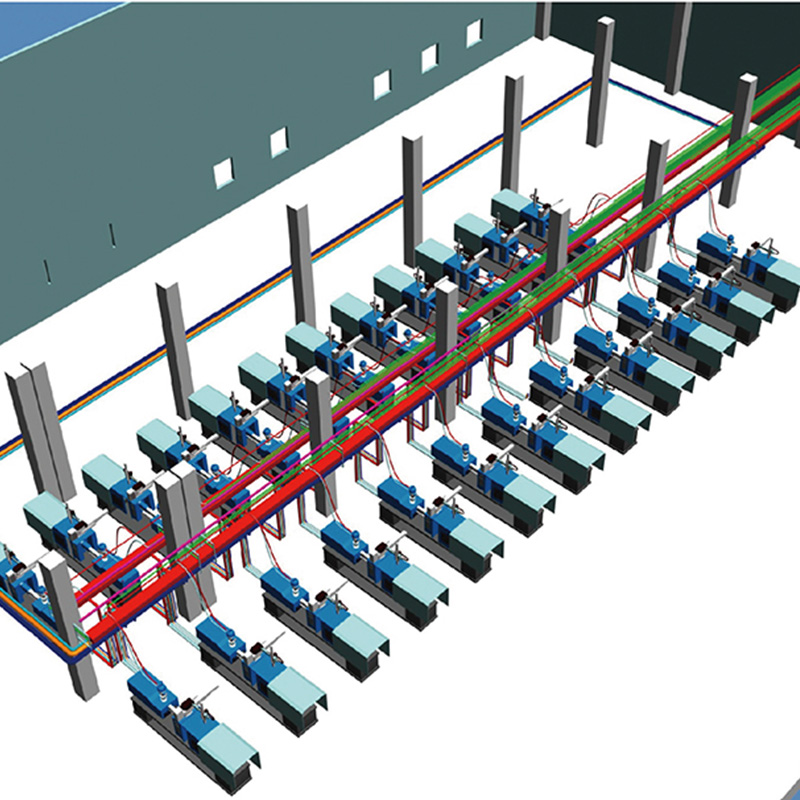

Manipulator parts find extensive applications across industries such as automotive manufacturing, electronics assembly, aerospace, pharmaceuticals, logistics, and beyond. These components enable automated processes such as welding, assembly, material handling, packaging, and inspection, thereby improving production throughput, quality consistency, and operational flexibility. Ongoing advancements in manipulator technology focus on enhancing autonomy, adaptability, and collaborative capabilities through innovations in artificial intelligence, machine learning, and human-robot interaction technologies.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى