Product Features:

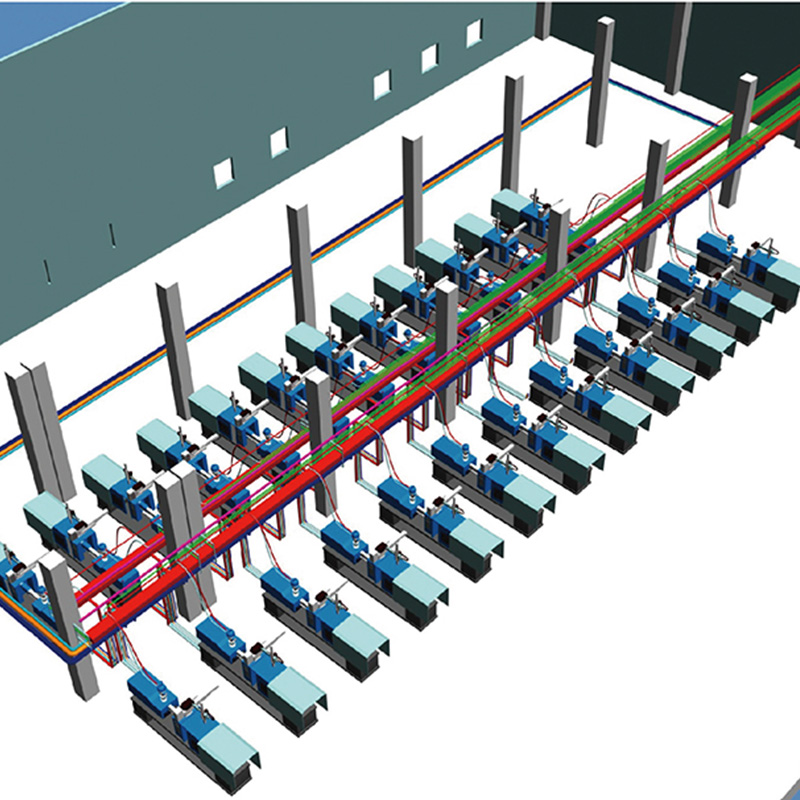

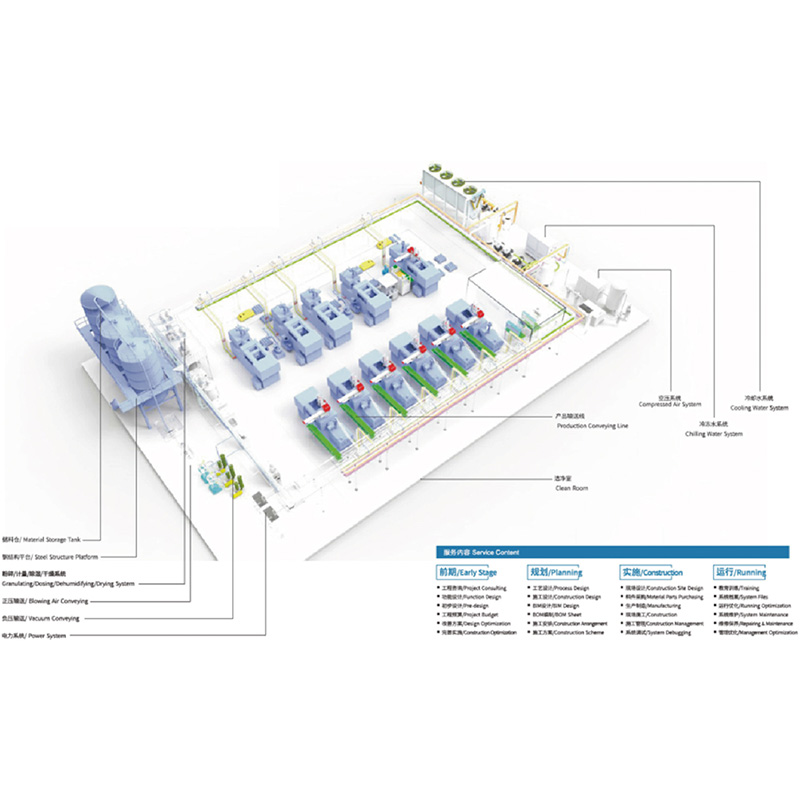

1. Intelligent water, gas and electricity system equipped with pipe and tube conveyance to ensure efficient supply of water, gas and other resources.

2. Cable tray and centralized feeding system use the main beam of the workshop to build a bracket for conveyance, making the workshop clean and tidy, and ensuring consistent arrangement of machine pipelines.

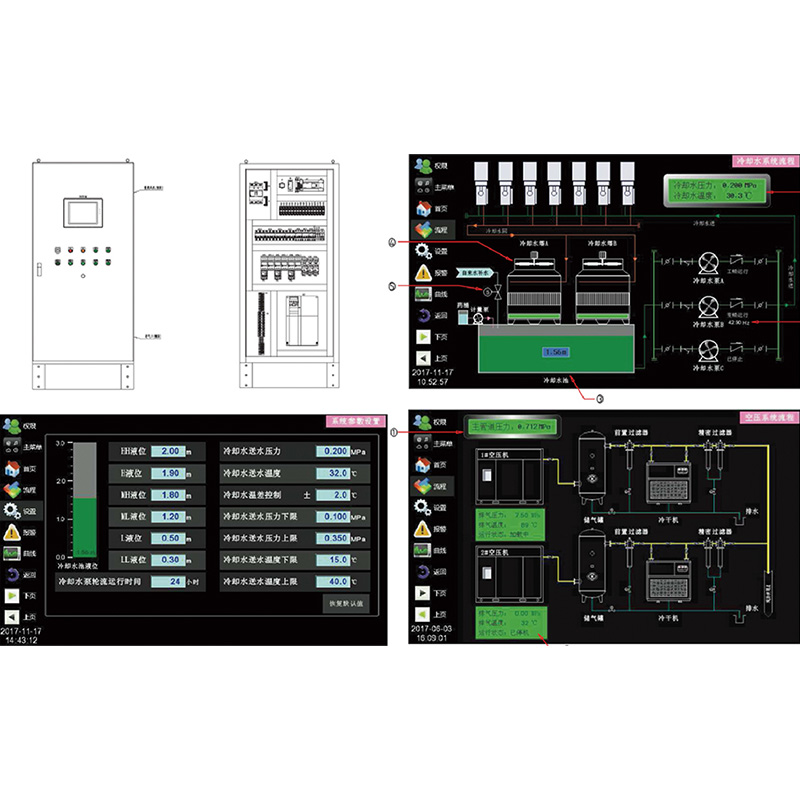

3. Automatic control of integrated control system to meet the production needs of various injection molding machines.

4. Equipped with automated management system for water and gas in the workshop, achieving constant pressure and constant flow water delivery, temperature detection to achieve intelligent start-up and shutdown of the cooling tower.

5. Real-time production testing and equipment intelligent alarm maintenance function, improving production efficiency and equipment reliability.

Product Advantages:

1. Efficient supply: The intelligent water, gas and electricity system can quickly and stably supply water, gas and other resources through pipe and tube conveyance, meeting the needs of injection molding machine production.

2. Workshop tidiness: The cable tray and centralized feeding system use the main beam of the workshop to build a bracket for conveyance, making the workshop clean and tidy, improving the comfort and safety of the working environment.

3. Automated control: The integrated control system can automatically adjust the supply of water, gas and other resources according to the production needs of injection molding machines, reducing the tediousness of manual operation and improving production efficiency.

4. Intelligent management: Equipped with an automated management system for water and gas in the workshop, it can achieve constant pressure and constant flow water delivery, temperature detection to achieve intelligent start-up and shutdown of the cooling tower, improving energy utilization efficiency and equipment stability.

5. Real-time monitoring and maintenance: The product has real-time production testing and equipment intelligent alarm maintenance functions, which can timely detect problems in the production process and take corresponding measures, improving equipment reliability and stability.

Product Details:

1. Pipe and tube conveyance: The intelligent water, gas and electricity system is equipped with pipe and tube conveyance, which can quickly and stably deliver water, gas and other resources to injection molding machines, ensuring continuity and stability of production.

2. Cable tray and centralized feeding system: The cable tray and centralized feeding system use the main beam of the workshop to build a bracket for conveyance, making the workshop clean and tidy, improving the comfort and safety of the working environment.

3. Integrated control system: The integrated control system can automatically adjust the supply of water, gas and other resources according to the production needs of injection molding machines, reducing the tediousness of manual operation and improving production efficiency.

4. Automated management system for water and gas in the workshop: Equipped with an automated management system for water and gas in the workshop, it can achieve constant pressure and constant flow water delivery, temperature detection to achieve intelligent start-up and shutdown of the cooling tower, improving energy utilization efficiency and equipment stability.

5. Real-time production testing and equipment intelligent alarm maintenance function: The product has real-time production testing and equipment intelligent alarm maintenance functions, which can timely detect problems in the production process and take corresponding measures, improving equipment reliability and stability.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى