Product Features:

1. High-precision positioning: Advanced servo control system is used to achieve high-precision position control and motion trajectory planning, ensuring accuracy and stability of the robot during operation.

2. Strong load-bearing capacity: The robot has a large load-bearing capacity, adaptable to different weight requirements for workpiece handling and assembly, improving work efficiency.

3. Flexible operation modes: The robot is equipped with various operation modes, including manual operation, automatic control, and remote control, meeting different production environments and process requirements.

4. Fast response and high speed: The robot has the characteristic of fast response, able to quickly complete various actions, improving production efficiency.

5. Safety and reliability: The robot adopts multiple safety protection measures, such as collision detection, overload protection, etc., ensuring the safety and reliability of the operation process.

Product Advantages:

1. Improve production efficiency: The high-speed movement and quick response capability of the robot can greatly reduce the production cycle, improve production efficiency, and bring greater economic benefits to the enterprise.

2. Reduce labor intensity: The robot replaces manual repetitive and strenuous work of handling and assembly, reducing the labor intensity of workers and improving the comfort of the working environment.

3. Improve product quality: The high-precision positioning and stability of the robot can ensure accurate assembly and processing of workpieces, reduce human errors, and improve product quality.

4. Flexibility: The robot has multiple operation modes, which can be flexibly adjusted according to different production needs to adapt to diverse production environments.

5. Cost savings: The use of robots can save labor costs, reduce personnel training and management expenses, and also reduce losses caused by human operational errors.

6. Improve safety: The robot adopts multiple safety protection measures, which can avoid accidents during worker operations, ensuring worker safety.

7. Scalability: The robot has scalability, which can be upgraded and modified according to the development needs of the enterprise to meet the production needs at different stages.

Product Application Range:

1. Manufacturing industry: The robot is widely used in industries such as automotive manufacturing, electronic manufacturing, and mechanical manufacturing for tasks like workpiece handling, assembly, welding, etc.

2. Logistics industry: The robot can be used for warehouse goods handling and sorting, improving logistics efficiency and reducing labor costs.

3. Medical industry: The robot can be used for medical equipment assembly and surgical assistance, improving surgical precision and safety.

4. Food industry: The robot can be used for food packaging, sorting, and handling processes, improving food processing efficiency and hygiene standards.

5. Aerospace industry: The robot can be used for aerospace component assembly and maintenance, improving work precision and safety.

Summary:

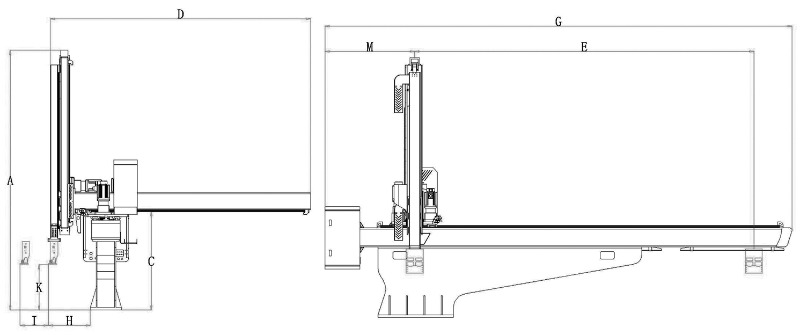

The five-axis servo bullhead type single arm dual section robot has features such as high-precision positioning, strong load-bearing capacity, flexible operation modes, fast response, and high speed, as well as advantages like improved production efficiency, reduced labor intensity, improved product quality, flexibility, cost savings, improved safety, and scalability. It is widely applied in various fields such as manufacturing industry, logistics industry, medical industry, food industry, and aerospace industry. This product can bring higher economic benefits and production efficiency to enterprises and is an essential device in modern industrial production.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى