Product Features:

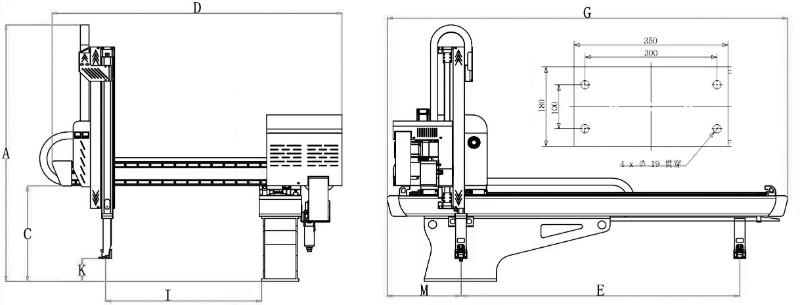

1. Three-axis servo drive: This robotic arm adopts an advanced three-axis servo motor drive system, featuring high precision, high speed, and high stability. Through precise servo control, it can achieve accurate positioning and motion control, meeting various complex operation requirements.

2. Lateral movement structure: Compared to traditional linear manipulators, the lateral movement structure can provide a larger working range and higher flexibility. The manipulator can move freely on the horizontal plane and can easily transfer from one workstation to another, greatly improving production efficiency.

3. Single-arm dual-section design: The manipulator adopts a single-arm dual-section design, allowing the arm to perform two different operations simultaneously. This design can improve production efficiency, reduce production cycles, and adapt to more work tasks.

4. Multiple gripper compatibility: The manipulator is equipped with multiple grippers that can be replaced according to different work tasks. Whether it is grasping, placing, assembling, or welding, the manipulator can handle them flexibly, meeting the needs of different industries.

5. User-friendly human-machine interaction: The manipulator is equipped with an intuitive operation interface and an easy-to-learn operation method. Operators can perform simple settings and operations through the touch screen, and can start using it after a brief training session.

Product Advantages:

1. Improve production efficiency: The three-axis servo lateral movement single-arm dual-section manipulator can perform multiple operations simultaneously, greatly improving production efficiency. Compared to traditional manual operations, the manipulator can work continuously without being affected by fatigue and human factors, thereby improving production efficiency and output.

2. Reduce labor costs: The manipulator can replace some heavy, dangerous, and repetitive tasks, reducing dependence on human resources. Through automated production, labor costs can be reduced, enhancing the competitiveness of the enterprise.

3. Improve product quality: The manipulator has high precision and stability, ensuring accuracy and consistency in each operation. Compared to manual operations, the manipulator can reduce the impact of human factors on product quality, improving product consistency and reliability.

4. Flexible adaptation to various work tasks: The manipulator is equipped with multiple grippers and tools that can be replaced according to different work tasks. Whether it is for workpieces of different sizes, shapes, or materials, the manipulator can handle them flexibly, meeting the needs of different industries.

5. Improve workplace safety: The manipulator can replace personnel for dangerous operations in environments such as high temperature, high pressure, and toxicity. Through automated production, operator safety can be protected and accidents can be reduced.

6. Programmability and intelligence: The manipulator is equipped with a programmable control system that allows programming and adjustment based on different work tasks. Through an intelligent control system, it can achieve automated production and remote monitoring, improving the controllability and manageability of the production process.

In summary, the three-axis servo lateral movement single-arm dual-section manipulator has high precision, high speed, and high stability features. It can improve work efficiency, reduce labor costs, enhance product quality, and improve workplace safety. Through flexible adaptation to various work tasks and intelligent control systems, the manipulator can meet the needs of different industries and bring greater competitive advantages to enterprises. Whether in manufacturing, logistics, or other industries, the three-axis servo lateral movement single-arm dual-section manipulator is an ideal automated production equipment.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى