Product Features:

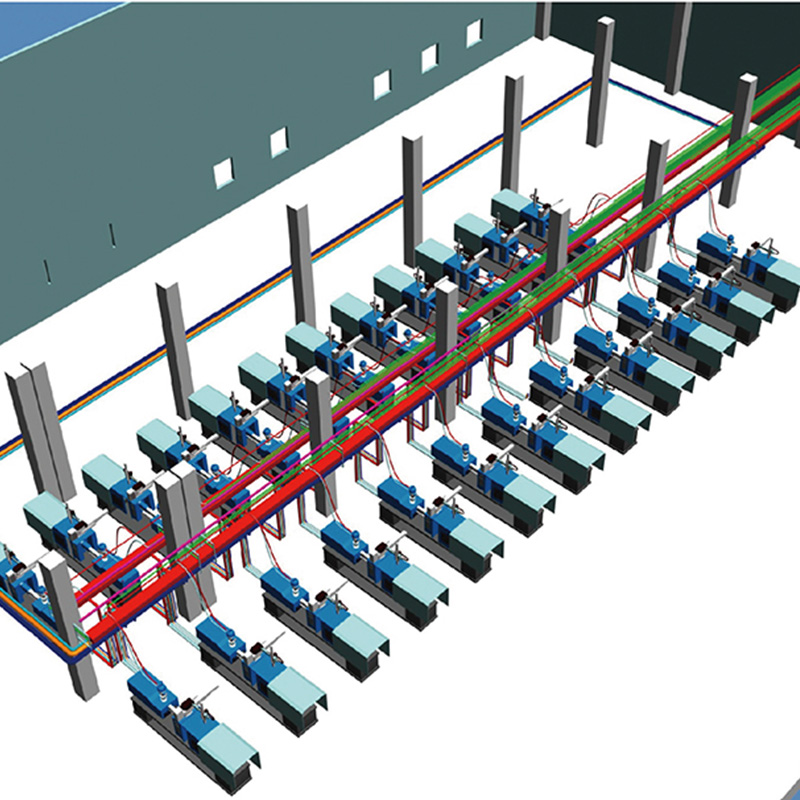

1. Material Durability: The aluminum alloy automated parallel conveyor belt is made of high-strength aluminum alloy material, which has corrosion resistance and wear resistance. It can maintain stable performance during long-term operation.

2. Automated Control: The conveyor belt is equipped with advanced automated control system, which can achieve precise material positioning and transportation, improving production efficiency and product quality.

3. Stable Operation: The aluminum alloy automated parallel conveyor belt uses precise transmission devices and stable conveying structure design to ensure that materials will not slide or bump during the transportation process, ensuring the safety and integrity of materials.

4. Strong Adaptability: The conveyor belt can be customized according to different production needs, suitable for material transportation in various industries and production lines, such as automotive manufacturing, electronics manufacturing, food processing, etc.

5. Easy Maintenance: The aluminum alloy automated parallel conveyor belt has a simple structure, making it easy to install and maintain, reducing downtime and maintenance costs.

Product Advantages:

1. Improve Production Efficiency: The aluminum alloy automated parallel conveyor belt can achieve continuous and stable material transportation, greatly improving the efficiency of the production line, reducing manual operations and waiting time, and increasing production capacity.

2. Reduce Labor Intensity: The automated control system can achieve automatic positioning and transportation of materials, reducing the labor intensity of workers, improving the safety and comfort of the working environment.

3. Improve Product Quality: The aluminum alloy automated parallel conveyor belt can achieve precise material positioning and transportation, avoiding errors and instability in manual operations, improving the consistency and quality of products.

4. Space Saving: The conveyor belt adopts parallel design, occupying a small area, making full use of workshop space, reducing the floor area of the production line, and improving space utilization.

5. Energy Saving: The aluminum alloy automated parallel conveyor belt uses efficient transmission devices and optimized design, which can reduce energy consumption, decrease energy consumption, and lower production costs.

6. Safety Enhancement: The conveyor belt is equipped with safety protection devices, which can detect and handle abnormal situations in a timely manner, ensuring the safe operation of the production line and reducing the occurrence of accidents.

7. Customizable: The aluminum alloy automated parallel conveyor belt can be customized according to specific customer needs, meeting the requirements of different industries and production lines, providing personalized solutions.

8. Long-term Stable Operation: The aluminum alloy automated parallel conveyor belt uses high-quality materials and advanced manufacturing processes, having the ability for long-term stable operation, reducing the frequency of maintenance and replacement, and lowering the usage cost.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى