Custom Linear Gantry Robot Manufacturer Factory For Sale

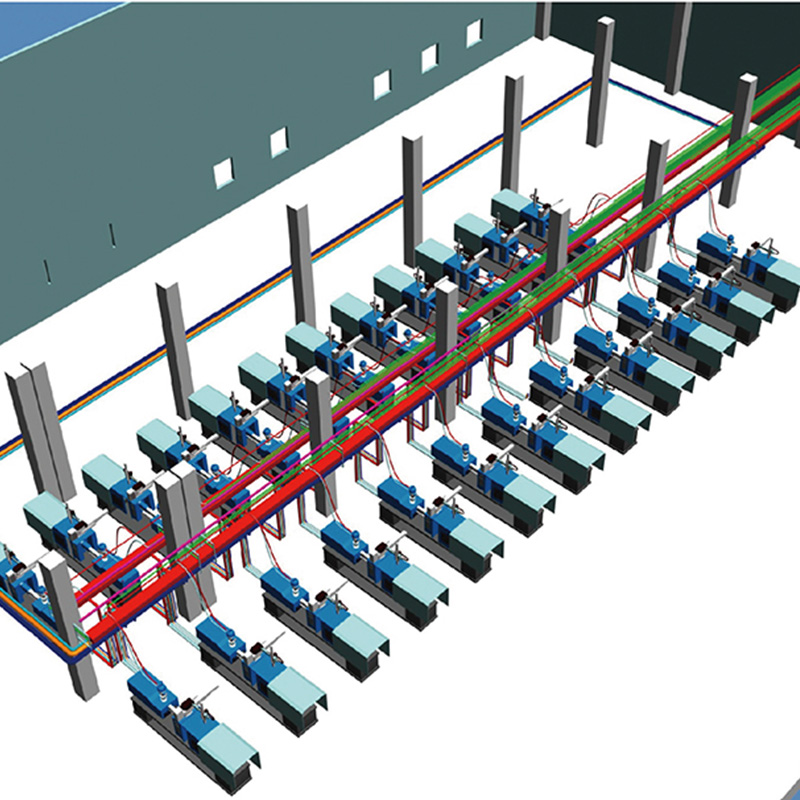

A gantry robot is a specialized type of robotic system characterized by its overhead-mounted structure and multi-axis movement capabilities. Unlike traditional robots that operate within a confined space, gantry robots traverse along a gantry or bridge, allowing them to cover large work areas while leaving the floor unobstructed. These robots are widely used in manufacturing and industrial applications for tasks such as material handling, assembly, pick-and-place, and inspection.

Gantry robots offer several advantages, including high-speed and high-precision movement, thanks to their stable gantry structure. They excel in applications requiring precise positioning and manipulation of workpieces, making them ideal for industries such as automotive, electronics, and aerospace. Additionally, gantry robots are highly versatile and customizable, with the ability to handle a wide range of payloads and adapt to various production requirements.

At the heart of gantry robots' appeal lies their ability to perform a wide range of tasks with speed, accuracy, and efficiency. Equipped with advanced sensors, actuators, and control systems, gantry robots can handle complex operations such as material handling, assembly, pick-and-place, and inspection with ease. This versatility makes them indispensable assets in modern manufacturing facilities, where agility and adaptability are paramount.

One of the primary advantages of gantry robots is their ability to big floor space utilization. Unlike traditional robotic systems that operate within a confined area, gantry robots are typically mounted overhead, allowing them to traverse large workspaces while leaving the floor unobstructed. This not only enhances safety and accessibility but also enables manufacturers to optimize their production layouts for greater efficiency and throughput.

Moreover, gantry robots excel in applications that require high-speed and high-precision movement. Their gantry structure provides stability and rigidity, allowing for precise positioning and manipulation of workpieces with small vibration or deviation. This level of precision is crucial in industries such as electronics, aerospace, and automotive manufacturing, where tight tolerances and quality standards are non-negotiable.

Another key advantage of gantry robots is their scalability and modularity. Manufacturers can customize gantry robot systems to meet their specific production requirements, whether it involves handling small components on a micro-scale or moving heavy payloads in a macro-scale environment. Additionally, gantry robots can be easily integrated with other automated systems and machinery, enabling seamless coordination and synchronization within the production line.

Furthermore, gantry robots contribute to improved workplace safety by reducing the need for manual labor in hazardous or repetitive tasks. By automating tasks such as heavy lifting, repetitive assembly, and hazardous material handling, gantry robots help small the risk of workplace injuries and accidents, creating safer and more ergonomic working environments for employees.

In addition to their operational benefits, gantry robots are driving advancements in efficiency and cost-effectiveness in manufacturing. By streamlining production processes and reducing cycle times, gantry robots help manufacturers increase their throughput and reduce lead times, ultimately enhancing their competitiveness in the global marketplace. Moreover, the precision and consistency offered by gantry robots translate into higher product quality and fewer defects, pilot to reduced scrap rates and lower production costs.

With ongoing advancements in robotics, AI, and machine learning, the potential applications and capabilities of gantry robots are only set to expand, ushering in a new era of efficiency and excellence in manufacturing.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى