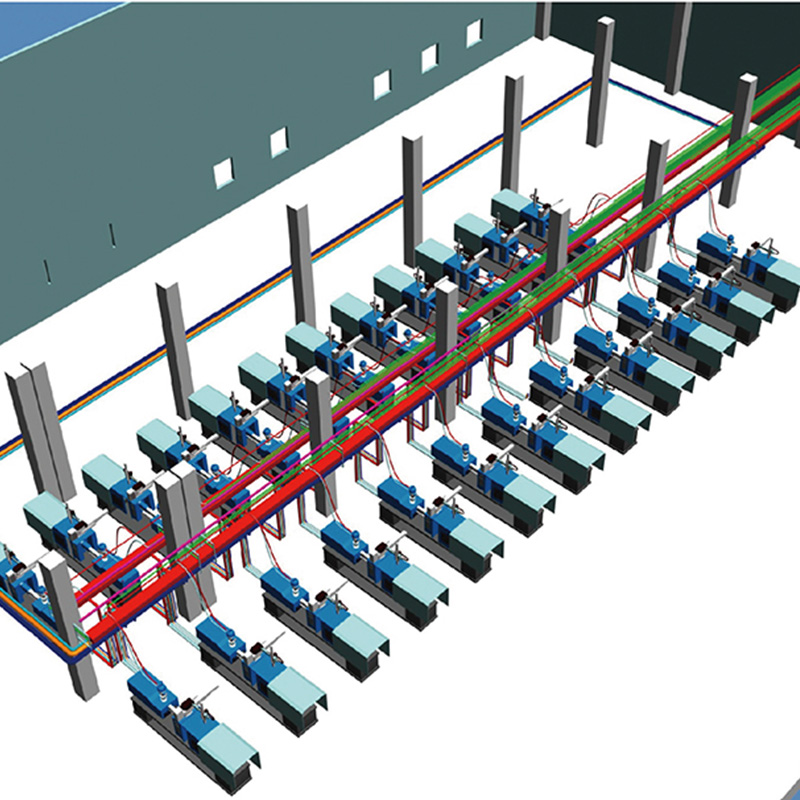

OEM High Quality Manipulator Parts Manufacturer Exporter

Manipulator parts are critical components in robotic systems and automation equipment, designed to enhance precision and efficiency in handling objects. These parts typically include arms, joints, end effectors, and control systems, each playing a specific role in the manipulation process.

The arms are often articulated, allowing for a range of motion that mimics human dexterity. Joints, such as rotary and linear actuators, facilitate movement and positioning, enabling manipulators to reach various angles and heights. End effectors, which can be grippers, suction cups, or specialized tools, are essential for securely grasping or interacting with objects.

Manipulator systems, or robotic arms, are pivotal in the automation of various industries, from manufacturing to healthcare. These systems are designed to replicate human-like movements, enabling them to handle tasks that are repetitive, dangerous, or require bad precision. The functionality of these systems is contingent upon a complex array of parts, each contributing to the overall performance.

Actuators are the muscles of the manipulator system, providing the force necessary for movement. They can be hydraulic, pneumatic, or electric, with each type offering different advantages in terms of power, speed, and control.

The end effector is the tool or device attached to the end of the manipulator arm. It is designed to interact with the environment, whether it's to grasp objects, apply force, or perform specialized tasks. The choice of end effector is highly dependent on the application.

The controller is the brain of the manipulator system. It interprets commands and coordinates the actions of the actuators and sensors. Modern controllers are often computer-based, utilizing sophisticated algorithms to ensure smooth and accurate operation.

Sensors play a critical role in providing feedback to the controller. They can detect a variety of conditions, such as temperature, pressure, or the presence of objects, allowing the manipulator to adapt its actions accordingly.

The transmission system connects the actuators to the mechanical components of the arm. It can be a series of gears, belts, or chains, responsible for transferring the motion and force from the actuators to the arm.

The power supply provides the necessary energy for the actuators and the controller. It can be an external source or an internal battery, depending on the design and application of the manipulator.

Safety is paramount in manipulator systems. Features such as emergency stop buttons, limit switches, and collision detection systems are integrated to prevent accidents and ensure the safety of both the equipment and the surrounding environment.

The software is the interface between the user and the manipulator system. It allows for programming, monitoring, and diagnostics. Advanced software can also enable machine learning capabilities, allowing the manipulator to improve its performance over time.

Cables and connectors are often overlooked but are essential for transmitting power and data throughout the manipulator system. They must be robust and reliable to withstand the rigors of industrial environments.

The structural components, such as the frame and joints, provide the physical support for the manipulator. They must be strong and durable to withstand the forces exerted during operation.

Manipulator systems are a testament to the ingenuity of modern engineering. Each part, from the actuators to the software, plays a crucial role in the system's operation.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى