A 2 Axis Gantry system is a versatile and cost-effective solution for applications requiring controlled movement in two axes, typically the X and Y axes. These systems consist of a gantry structure, linear motion components, and a moving platform or bridge.

- Two-axis movement: The primary advantage of a 2 Axis Gantry system is its ability to move in two perpendicular directions, providing a wide range of motion and access to the workspace.

- Modular design: These systems can be easily customized to suit specific application requirements, including the addition of various end-effectors, sensors, or other peripherals.

- Cost-effective: Compared to more complex multi-axis systems, 2 Axis Gantry systems offer a more affordable solution for applications with limited motion requirements.

- Material handling: 2 Axis Gantry systems are commonly used for moving and positioning materials in manufacturing processes, such as loading and unloading machines or assembling components.

- Inspection and quality control: These systems can be equipped with cameras or other sensors to perform precise inspections of products or components.

- Pick and place operations: In assembly lines, 2 Axis Gantry systems can be used to pick up and place components in specific locations with high accuracy.

A Gantry Manipulator is a more advanced version of the 2 Axis Gantry system, designed to provide additional functionality and flexibility. These systems typically include a third axis of movement, allowing for greater versatility in handling tasks.

- Three-axis movement: The addition of a third axis, usually the Z-axis, enables the Gantry Manipulator to move vertically, providing access to a larger workspace.

- Enhanced precision: Gantry Manipulators are designed to offer high levels of accuracy and repeatability, making them suitable for tasks requiring fine control.

- Integrated tool changers: Some Gantry Manipulators can be equipped with tool changers, allowing them to switch between different tools or end-effectors quickly and efficiently.

- Machining and milling: Gantry Manipulators are often used in CNC machining centers, where they can hold and maneuver cutting tools with high precision.

- Welding and fabrication: In welding applications, Gantry Manipulators can hold and position welding torches or other welding equipment, improving the quality and consistency of welds.

- Material cutting: These systems can be used to hold and maneuver cutting tools, such as plasma or laser cutters, for precise material cutting operations.

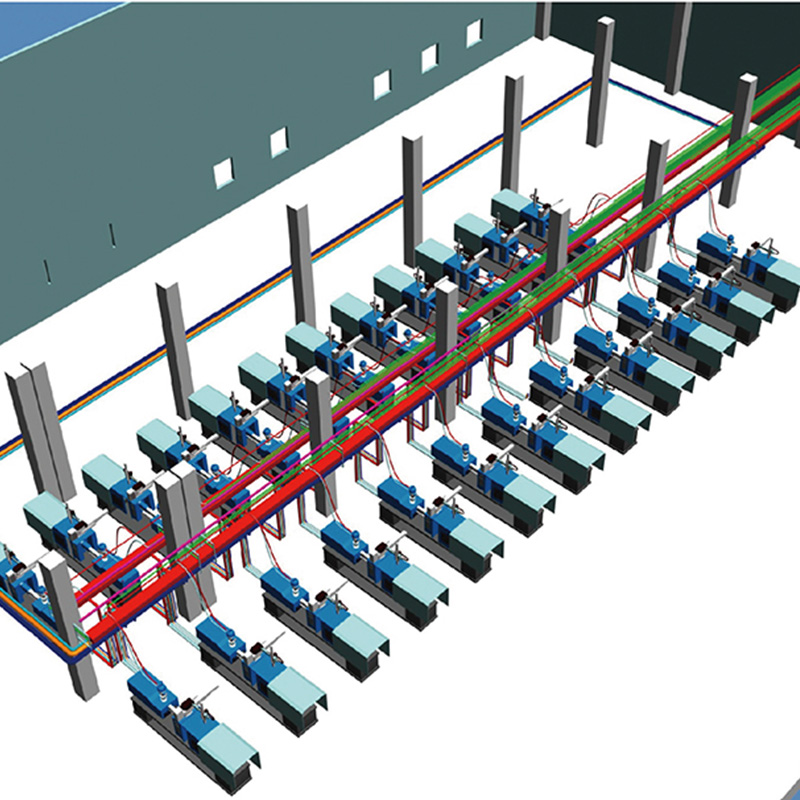

A Cartesian Gantry Robot is a highly advanced and flexible automation solution that combines the benefits of both 2 Axis Gantry and Gantry Manipulator systems. These robots offer three-axis movement and are designed for high-speed, high-precision applications.

- Three-axis movement: Cartesian Gantry Robots provide movement in the X, Y, and Z axes, allowing for complex and intricate movements within the workspace.

- High-speed operation: These robots are designed for rapid movement and quick response times, making them ideal for high-speed manufacturing processes.

- Advanced control systems: Cartesian Gantry Robots are equipped with sophisticated control systems that enable precise and coordinated movement of the robot's axes.

- High-speed assembly: Cartesian Gantry Robots are well-suited for high-speed assembly tasks, where components must be positioned and assembled with bad accuracy and speed.

- Precision machining: In precision machining applications, these robots can hold and maneuver cutting tools with exceptional accuracy, ensuring high-quality results.

- Automated inspection: Cartesian Gantry Robots can be equipped with cameras or other sensors to perform automated inspections of products or components, improving quality control and reducing the risk of human error.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى