The field of robotics is undergoing rapid advancements, with innovations emerging in various forms, including mechanical tentacle arms, micro robot arms, and professional robotic arms. These diverse robotic arms are revolutionizing industries from healthcare to manufacturing with their unique capabilities and applications.

Inspired by nature, mechanical tentacle arms mimic the flexibility and dexterity of an octopus tentacle. These arms are composed of multiple segments connected by flexible joints, allowing them to bend and twist like biological tentacles.

One of the key advantages of mechanical tentacle arms is their ability to navigate complex and confined spaces with ease. Their flexible design enables them to reach into tight spaces or navigate around obstacles, making them ideal for tasks that require intricate movements.

Moreover, mechanical tentacle arms offer enhanced adaptability compared to traditional robotic arms. Their segmented structure allows for a greater range of motion and flexibility, making them well-suited for applications such as surgery, underwater exploration, and delicate assembly tasks.

Furthermore, these arms can be equipped with various sensors and cameras to provide real-time feedback and enhance their capabilities. This allows them to adapt to changing environments and perform tasks with greater precision and accuracy.

Micro robot arms represent another fascinating area of robotic innovation, focusing on miniaturization and precision. These tiny robotic arms are designed to handle tasks at a microscopic level, making them ideal for applications in microelectronics, medical procedures, and research.

Despite their small size, micro robot arms are capable of performing complex tasks with incredible precision. Their compact design and high-resolution control systems enable them to manipulate objects at a sub-millimeter scale, opening up new possibilities in fields such as nanotechnology and microsurgery.

Additionally, micro robot arms can be integrated with advanced imaging and sensing technologies to enhance their capabilities. This allows them to navigate and interact with microscopic environments more effectively, facilitating breakthroughs in research and development.

Furthermore, the development of micro robot arms is driving advancements in materials and manufacturing techniques. Researchers are exploring new materials and fabrication methods to create smaller, more efficient robotic components, pushing the boundaries of what is possible in robotics.

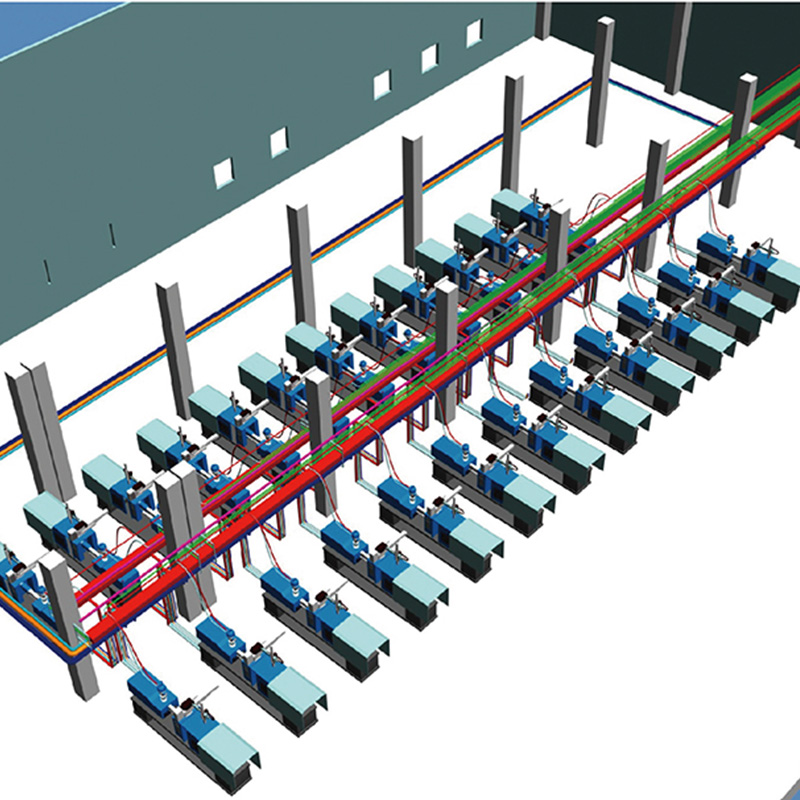

Professional robotic arms represent the traditional and more widely recognized form of robotic arms used in industries such as automotive manufacturing, aerospace, and logistics. These robust and versatile arms are designed to handle heavy loads and perform repetitive tasks with high precision and efficiency.

One of the key strengths of professional robotic arms is their scalability and customizability. They can be tailored to meet the specific requirements of various industries, from welding and painting to material handling and assembly.

Moreover, professional robotic arms are equipped with advanced control systems and software that optimize their performance and adaptability. These systems enable the arms to work collaboratively with humans, enhancing productivity and safety in the workplace.

Furthermore, the integration of sensors, cameras, and artificial intelligence technologies is transforming professional robotic arms into intelligent systems capable of autonomous decision-making. This allows them to adapt to changing conditions, learn from experience, and optimize their operations over time.

The future of robotics is bright and diverse, with innovations emerging in mechanical tentacle arms, micro robot arms, and professional robotic arms. Each type offers unique capabilities and applications that are reshaping industries and pushing the boundaries of what is possible in robotics.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى